In engineering surveys, workers are required to correctly master the use of inclinometers and treat them with a professional attitude. Inclinometers are widely used in water conservancy and hydropower, mining and metallurgy, transportation and urban construction in the field of geotechnical engineering. They are used to measure the angle of engineering structures (such as boreholes, foundation pits, foundations, walls and dam slopes) and the azimuth angle of the instrument.

The inclinometer has excellent performance, strong durability, high precision and fast response. Compiling computer programs according to the inclinometer parameters and related calculation formulas can form an automated monitoring system with data collection and analysis functions. The methods of using different inclinometers are similar.

How to use the inclinometer

1.Preliminary preparation

Arrangement of observation points and formation of holes: Observation points should be arranged reasonably according to local conditions. It is usually required that the horizontal distance between adjacent observation points is the depth of a hole, and the observation points can be appropriately reduced or reduced according to the geotechnical engineering level. During construction, plumb hammer should be used as much as possible, and the deflection angle should be less than 2°. The diameter of the final hole should be 30mm larger than the outer diameter of the inclinometer, and the drilling depth should be 5m larger than the deepest displacement zone. Before embedding the inclinometer, all boreholes should be inspected and accepted, and they can be embedded only after they are qualified.

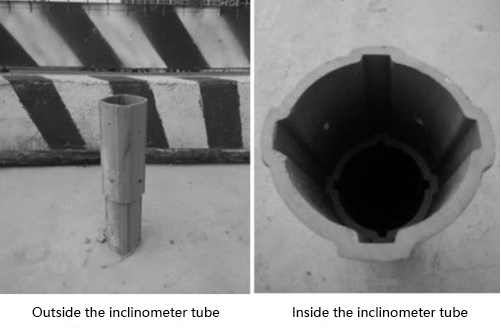

Installation of inclinometer:

1) Install the inclinometer on the bottom cover and fix it with screws or glue;

2) Insert the inclinometer into the borehole one by one, connect the inclinometer and the inclinometer with the connecting pipe, and fix them with screws. When installing the inclinometer, please pay attention to the direction of the guide groove. The direction of the guide groove must be consistent with the direction specified in the design requirements. Put the assembled inclinometer into the borehole one by one until it reaches the orifice;

3) After confirming that the inclinometer is installed correctly, it can be backfilled. During the backfilling process, water should be injected every 3 ~ 5m to make the backfill and the hole wall firmly combined until it reaches the orifice;

4) The part of the inclinometer exposed on the surface is poured concrete to form a concrete pier to protect the stability of the nozzle and corner of the inclinometer. The concrete pier should be equipped with displacement and settlement observation points;

5) Protect the inclinometer exposed to the ground and cover the pipe cover to prevent objects from falling into it;

6) After installation, use the analog inclinometer to test, and try to place the two guide grooves of the 90° inclinometer from to bottom to ensure that the analog inclinometer passes smoothly along the inclinometer.

The assembly of the inclinometer:

Before the test, the inclinometer must be checked and calibrated, and the preparatory work before the test is performed before assembly.

2. Test process

First put the inclinometer into the inclinometer tube, so that the guide wheel is locked into the guide groove. The direction should be: when the positive direction of the guide wheel is consistent with the positive direction of the measured displacement coordinate (+ X), the measured value is positive, and vice versa. Then, according to the mark on the cable, measure the inclination angle of the inclinometer axis relative to the reference axis for each basic length. The test method should follow the following two points: When the lower part of the inclinometer is reliably fixed in the bedrock (the buried depth should be greater than 5000mm), it can be determined that the bedrock has no displacement. At this time, you can measure from bottom to until the nozzle. When the bottom of the inclinometer is suspended (the bottom is not fixed on the bedrock), the measurement should be performed from to bottom.

3. Data collection and analysis

Data collection and analysis usually adopt automated integrated processing systems. The automated integrated processing system can effectively improve work efficiency and quality. It is compiled into a computer program based on the inclinometer parameters and related calculation formulas, and the data is output in the form of intuitive tables and graphics.

The inclinometer has high measurement accuracy and can be operated in places beyond the reach of manpower. It is an important tool for engineering surveys and brings many conveniences to engineering surveys. It is necessary for survey personnel to master the use of inclinometers.

+86 189 2129 2620

+86 189 2129 2620

+86 176 0611 8008 sales@bwsensing.com

sales@bwsensing.com