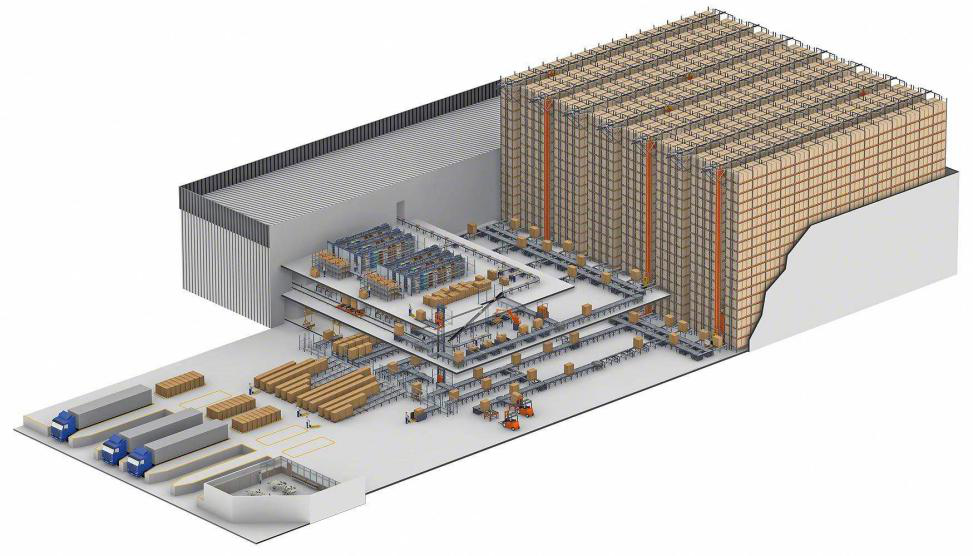

Stereoscopic warehouse refers to a warehouse that uses high-rise shelves with boxes or pallets to store goods, and uses lanes to stack heavy machines and other machinery for operations. Three-dimensional warehouses are generally tall, equipped with multi-layer shelves, the height of which is generally above 5 meters, and the highest is 40 meters. The common three-dimensional warehouses are between 7 and 25 meters. It is difficult to manually import and export the shelves. Must rely on machinery for automated operations.

Through scientific design, unfavorable factors are reduced and the safety of the three-dimensional warehouse is guaranteed. In terms of installation performance, such a large project as an automated warehouse requires planning of the entire site before installation and operation. The weight of the equipment in the three-dimensional warehouse is very heavy. During the long-term use, it will cause great damage to the warehouse floor and wear the base of the equipment itself. When designing a three-dimensional warehouse, it is necessary to make a scientific and reasonable design of the load-bearing capacity of the warehouse, design a ground that can withstand this pressure, and reduce the degree of wear of related equipment and ground.

Different goods in the warehouse have a big gap in the requirements of the ground. It is necessary to take into account factors such as slip resistance and impact resistance, and strive to ensure that the final design of the warehouse floor can meet the storage requirements of different types of goods. Taking into account the characteristics of various types of goods, the area of the warehouse should be clearly divided, which can effectively improve the storage capacity of the warehouse, and can also avoid damage to the goods due to storage environment factors to a certain extent.

In the process of use, the operation of warehouse management personnel affects the safety of the three-dimensional warehouse to a certain extent. Professional skills operation training should be carried out, and the operation should be strictly in accordance with standardized procedures. Automated equipment is different from traditional warehouses. Managers need to be trained and have a certain knowledge of science and technology. Regular maintenance and maintenance should be done during the use of the equipment to prevent malfunctions.

Based on the risk assessment, the scientific design of the three-dimensional warehouse safety from all aspects and pre-maintenance can avoid the waste of property and resources caused by blind unplanned decision-making, make the operation more intuitive and simple, and achieve the purpose of long-term safe operation at the lowest cost.

+86 189 2129 2620

+86 189 2129 2620

+86 176 0611 8008 sales@bwsensing.com

sales@bwsensing.com