BWSENSING reached in-depth cooperation with major wind turbine manufacturers a few years ago. Our advanced sensing technology has successfully helped monitor the wind turbines and realized the comprehensive status monitoring of wind turbines. This technological breakthrough will bring great progress to the wind power industry and ensure the stable operation of power generation wind turbines.

Traditionally, the monitoring of wind turbines mainly relies on manual inspection and regular maintenance. This method has certain limitations, because these huge structures are usually distributed over a wide geographical area, making it difficult to perform real-time monitoring and fault diagnosis. This means that it is impossible to detect potential faults in time, and it is difficult to accurately judge the operating status of equipment. As the main component of modern renewable energy, wind turbines play an important role in supplying clean and sustainable electricity. However, the stability and safety of tall towers in adverse weather conditions has always been a challenge for the industry. Under the wind force, the tower is subjected to huge pressure and vibration, and is prone to problems such as fatigue, corrosion, cracks, and even collapse, which affects its structural stability and operational safety. In order to solve this problem, BWSENSING has worked closely with wind turbine manufacturers to develop a series of advanced intelligent tower monitoring solutions.

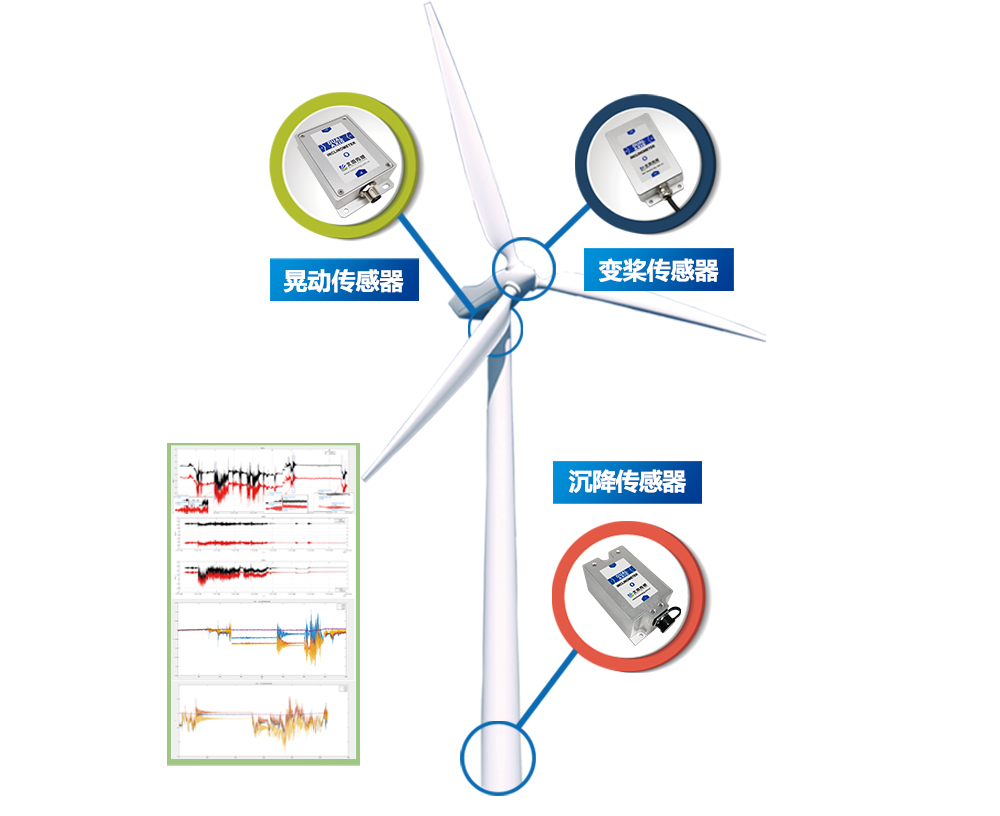

The sensor system developed by BWSENSING adopts advanced Internet of Things technology and algorithm, which can monitor various indicators and status of power generation wind turbines in real time. The system is installed in key parts of wind turbines. It cooperates with cloud monitoring software to quickly identify working condition such as uneven settlement and abnormal vibration of the tower, and can complete the calculation; uploading; displaying and storage of tilt displacement of the tower; uneven settlement of the tower foundation; blade vibration; unit mechanical vibration state characteristics such as the total value of vibrationon, in order to realize automatic and accurate early warning and rapid positioning in combination with working condition information and multi-directional monitoring of wind turbines.

Among them, the product FDVG528E dynamic inclination sensor, which was applied to the Xinjiang Goldwind Sci & Tech Co.,Ltd. project in June 2023 and installed on the main cabin for real-time inclination monitoring, is a surge (shock) immunity that reaches IEC 61000-4-5 level IV attitude measuring equipment. It can measure the inertial attitude parameters of rolling and pitching as well as angular velocity and acceleration of the moving carrier. Its attitude deviation is estimated by a 6-state Kalman filter with appropriate gain, which is suitable for inclination measurement in motion or vibration state. FDVG528E uses high-quality and reliable MEMS accelerometers and gyroscopes, and uses algorithms to ensure measurement accuracy. At the same time, the sealed design and strict process ensure that the product can still accurately measure the attitude parameters of the carrier in harsh environments. And through various compensations such as nonlinear compensation, quadrature compensation, temperature compensation and drift compensation, the error caused by interference can be greatly eliminated and the product accuracy level can be improved. At the same time, FDVG528E has a digital interface and an analog interface, which can be easily integrated into the user's system.

Applied in the CRRC project in November 2022, the BW-VG228 dynamic inclination sensor product installed on the hub of the wind turbine for real-time azimuth monitoring is a low-cost attitude measurement device that can measure the roll, pitch and angular velocity of the moving carrier and inertial attitude parameters for acceleration. Its attitude deviation is estimated by a 6-state Kalman filter with appropriate gain, which is suitable for inclination measurement in motion or vibration state. VG228 uses high-quality and reliable MEMS accelerometers and gyroscopes, and uses algorithms to ensure measurement accuracy. At the same time, the sealed design and strict process ensure that the product can still accurately measure the attitude parameters of the carrier in harsh environments. Through various compensations such as nonlinear compensation, quadrature compensation, temperature compensation and drift compensation, the product can greatly eliminate the error caused by interference and improve the accuracy level of the product. VG228 has a digital interface, which is convenient for users to integrate into the system. In addition, we can also provide dynamic inclination sensors with 485, CAN and other communication methods for wind power enterprises to choose.

Through the continuous monitoring of BWSENSING, wind turbine operators can obtain accurate data on tower structure and vibration in time. This data can be used to identify potential structural problems or signs of fatigue in the tower, and to help develop timely maintenance plans to reduce potential risks and failures. In addition, the system can also has real-time early warning and alarm functions, and timely notify relevant personnel to take necessary preventive measures.

The application of this innovative technology has brought great benefits to the wind power industry. First of all, through online real-time monitoring and remote data transmission, wind power companies can keep abreast of the operating status of equipment, reduce downtime due to failures, and improve power generation and economic benefits. Secondly, the use of machine learning algorithms to analyze a large amount of sensor data can give early warning of possible equipment failures and take timely maintenance measures to reduce maintenance costs and risks. In addition, comprehensive condition monitoring can also help optimize equipment operation and maintenance plans, prolong equipment life, and improve reliability.

The innovative achievements of BWSENSING have attracted widespread attention in the wind power industry. At present, the company has cooperated with a number of wind power companies to apply its sensor system to projects, and has achieved remarkable results. The successful application of this technology will further promote the development of the wind power industry and make an important contribution to the sustainable utilization of clean energy.

Mr. Li, the sales manager of BWSENSING, said: "We are very proud of our sensor system being successfully applied to the monitoring of wind turbine towers. This technological innovation will greatly improve the safety and efficiency of the renewable energy industry, and lay a solid foundation for the future.”

With the leading position and innovative ability of BWSENSING, the wind power industry will has a new milestone, which can make better use of modern technology to ensure the stable operation of wind turbines and maximize energy output. This will provide a stronger foundation for global renewable energy development and drive progress towards a cleaner and more sustainable energy future.

+86 189 2129 2620

+86 189 2129 2620

+86 176 0611 8008 sales@bwsensing.com

sales@bwsensing.com