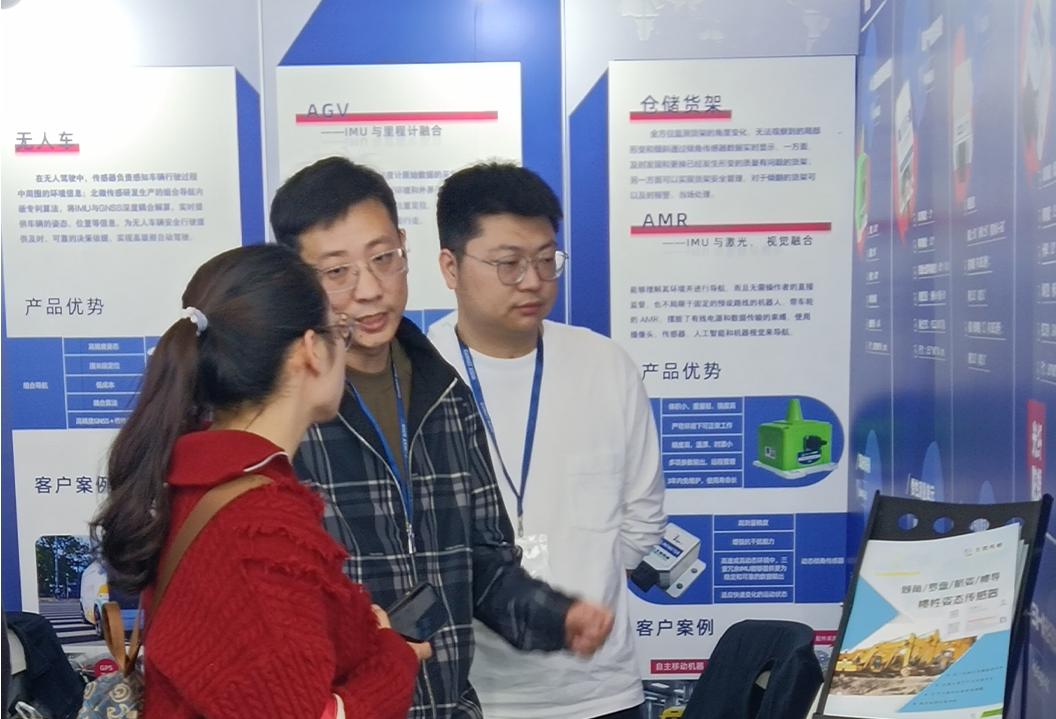

Recently, BWSENSING participated in the Shanghai Logistics Exhibition (CeMATASIA) held at the Shanghai New International Expo Center from November 5 to 8, 2024. As an international event in the field of logistics technology and transportation systems, the Shanghai Logistics Exhibition has attracted the attention of many top companies and professionals around the world. BWSENSING brought its deeply innovative inertial attitude sensor technology and a series of highlight products to showcase its outstanding contributions and cutting-edge solutions in the logistics industry.

In the logistics industry, positioning accuracy and path planning have always been a problem that has plagued companies. Traditional positioning methods often have errors and are difficult to meet the needs of high-precision logistics. To address this problem, BWSENSING has launched an innovative solution using inertial attitude sensor technology.

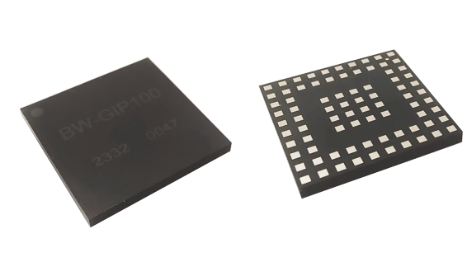

Ultra-low-cost micro-inertial navigation system

BWSENSING's ultra-low-cost micro-inertial navigation system (IMU) achieves high-precision positioning through integration with the odometer. In practical applications, due to problems such as wheel slippage and cumulative errors, the odometer data obtained using encoders alone often has certain deviations. The IMU of BWSENSING can collect acceleration and angular velocity information in real time. By integrating with the odometer data, it effectively eliminates the installation error and odometer error of the IMU, and eliminates the drift of the gyroscope, thereby achieving high-precision positioning. This solution greatly improves the accuracy and efficiency of logistics transportation and reduces the error rate during transportation.

Multi-redundant dynamic tilt sensor

BWSENSING's multi-redundant dynamic tilt sensor has also attracted much attention. The sensor improves the reliability and stability of measurement by adopting a multi-sensor redundant design. In logistics warehousing and automated production lines, the tilt and collapse of goods are common safety hazards. BWSENSING's multi-redundant dynamic tilt sensor can monitor the tilt changes of goods in real time. When the tilt of the goods exceeds the safe range, the system will immediately issue an alarm to remind the operator to take timely measures to avoid accidents. This solution provides a safer and more reliable guarantee for logistics warehousing and automated production lines.

Seven-axis combined navigation microsystem

BWSENSING's seven-axis combined navigation microsystem integrates a variety of sensors and advanced algorithms to achieve all-round and high-precision navigation and positioning of logistics and transportation equipment. The system not only has powerful navigation and positioning functions, but also has excellent environmental adaptability and anti-interference capabilities, and is suitable for logistics and transportation tasks in various complex environments. Its miniature size is also very easy to integrate, greatly increasing space utilization while ensuring performance.

BWSENSING's innovative applications in the logistics industry have been widely recognized. With advanced technology and high-quality products, the company has successfully served many well-known logistics companies and projects, and has accumulated rich application experience and successful cases. At this Shanghai Logistics Exhibition, BWSENSING used its latest innovative strength and solutions in the logistics industry to promote the intelligent development of the logistics industry.

+86 189 2129 2620

+86 189 2129 2620

+86 176 0611 8008 sales@bwsensing.com

sales@bwsensing.com